A grease gun applies lubrication to machinery and equipment. It ensures smooth operation and reduces wear and tear on moving parts.

Grease guns are essential tools in various industries, from automotive to manufacturing. They help maintain equipment by delivering grease precisely where it’s needed.

Lubrication prevents rust, corrosion, and mechanical failure, ultimately extending the lifespan of machines. Grease guns come in various types, including manual, pneumatic, and battery-operated.

This article is about what a Grease gun is used for. Learn more…

The Essence of Grease Guns

A grease gun is a handy tool used for applying lubricants. It helps keep machines and vehicles running smoothly. Grease guns are essential for maintaining bearings, joints, and other moving parts.

Key functions of grease guns include:

- Easily apply grease to hard-to-reach areas.

- Prevent wear and tear on machinery.

- Reduce friction between parts.

Types of Grease Guns include:

| Type | Description |

|---|---|

| Manual | Operated by hand for precise control. |

| Pneumatic | Uses air pressure for quick application. |

| Electric | Powered by electricity for easy use. |

Mechanics of Grease Gun Operation

A grease gun is a tool used to apply lubrication to machinery. Loading the grease is the first step. Use a grease cartridge or bulk grease. Ensure the gun is clean before loading. Insert the cartridge into the gun and secure it tightly.

Next, release air from the gun. This helps in smooth operation. Pump the handle to push grease through the nozzle. The grease flows out when pressure is applied. Adjust the nozzle for accurate placement. This ensures that grease reaches all necessary parts.

| Step | Description |

|---|---|

| 1 | Load the grease cartridge. |

| 2 | Clean the grease gun. |

| 3 | Release air from the gun. |

| 4 | Pump the handle to deliver grease. |

Grease Gun Variants

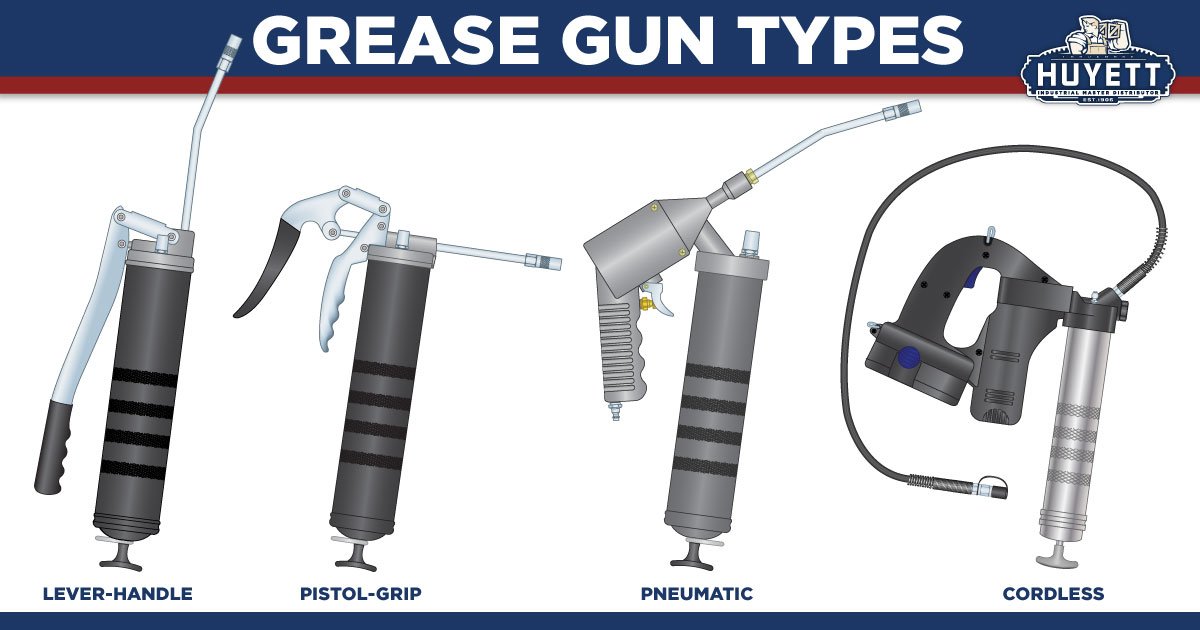

Credit: www.huyett.com

A grease gun is a handy tool for applying lubricants. It helps keep machines running smoothly. Different types of grease guns exist to suit various needs.

Manual grease guns require physical effort. Users pump a handle to dispense grease. They are simple and effective for small tasks.

Pneumatic grease guns use compressed air to deliver grease. They save time and energy, making them great for larger jobs. These guns offer a steady flow of lubricant.

Electric grease guns operate with a battery or power source. They provide consistent pressure and are easy to use. Ideal for frequent lubrication tasks, they reduce hand fatigue.

Applications In Various Industries

A grease gun is essential in many industries. In automotive maintenance, it helps keep parts running smoothly. Continuous lubrication prevents wear and tear on engines and gears. This simple tool makes it easy to apply grease exactly where it is needed.

For heavy machinery lubrication, a grease gun ensures machines operate efficiently. It protects components from dirt and moisture.

Grease guns also benefit agricultural equipment. They help maintain tractors and other machinery. Proper lubrication reduces breakdowns and improves overall performance. Farmers rely on this tool for smooth operations.

Precision Lubrication

A grease gun is essential for precision lubrication. It delivers the right amount of grease to the machinery. Different attachment options allow for versatile use. Choose from flexible hoses, rigid extension tubes, or nozzles. Each attachment fits various applications effectively.

Avoiding over- or under-lubrication is crucial. Over-lubrication can cause grease to leak and damage parts. Under-lubrication may lead to wear and tear. Using the right attachment helps control the amount of grease applied.

| Attachment Type | Best For |

|---|---|

| Flexible Hose | Tight spaces |

| Rigid Tube | Hard-to-reach areas |

| Nozzle | Precise application |

Maintenance Tips for Grease Guns

Credit: ronixtools.com

Cleaning of grease guns is very important. This prevents dirt from mixing with grease. Always wipe the grease fitting after each use. Clean the nozzle and tip to avoid clogs. Use a clean cloth to remove old grease.

Proper storage practices help maintain the grease gun’s condition. Store it in a dry place to prevent rust. Avoid exposing it to extreme temperatures. Keep it away from direct sunlight. Ensure the cap is on the nozzle when not in use.

Safety Protocols

Credit: ibtinc.com

Using a grease gun safely is very important. When greasing, wear protective gear. This includes gloves, goggles, and long sleeves. Protective gear helps prevent injuries.

Handling pressurized equipment requires care. Always check for leaks before use. Keep the nozzle pointed away from people. Avoid using a damaged grease gun.

Follow these steps for safe handling:

- Check the grease gun for damage.

- Wear protective gloves and goggles.

- Keep your hands dry to avoid slipping.

- Store the gun in a safe place.

Frequently Asked Questions About Grease Guns

What is the best grease gun?

The best grease gun depends on your needs. For heavy-duty tasks, the Lincoln 1162 Air Operated Grease Gun is highly reliable and efficient. For portability, the DEWALT DCGG571M1 20V Max Cordless Grease Gun offers excellent performance and convenience. For manual use, the Plews 05-006 10 oz Grease Gun is durable and easy to operate. Choose based on your usage frequency, power source preference, and the type of lubrication required.

Who makes the best grease gun?

The best grease gun is subjective and depends on specific needs, but top brands like Lincoln, Milwaukee, and DeWalt are highly regarded. Lincoln offers durability and precision, Milwaukee excels in cordless innovation, and DeWalt provides reliable performance. Ease of use, battery life (for cordless grease gun), and grease output should guide your choice. Ultimately, the best grease gun is one that suits your application, whether for automotive, industrial, or home use.

How much is a grease gun?

A grease gun typically costs between 20 and 100 dollars, depending on the type and quality. Manual grease guns are more affordable, ranging from 20 to 50, while pneumatic or electric models can cost 50 to 100 or more. High-end, professional-grade grease guns may exceed $100. Prices also vary based on brand, features, and included accessories.

What are the common uses of a grease gun?

Grease guns are commonly used to lubricate machinery and equipment, ensuring smooth operation and reducing wear. They are essential in automotive maintenance for greasing chassis components, bearings, and joints. In industrial settings, they lubricate conveyor systems, motors, and heavy machinery. Agricultural equipment, such as tractors and harvesters, also relies on grease guns for maintenance.

What type of tool is a grease gun?

A grease gun is a handheld tool used to apply lubricant, typically grease, to mechanical components such as bearings, joints, and fittings. It ensures smooth operation and reduces friction and wear in machinery. Grease guns come in manual, pneumatic, and electric varieties, with a trigger or lever mechanism to dispense grease through a nozzle. They are essential for maintenance in automotive, industrial, and agricultural applications.

Why does my grease gun leak?

A grease gun may leak due to a worn or damaged O-ring, over-pumping causing excess pressure, or a faulty seal. Improper assembly or using the wrong type of grease can also lead to leaks.

Why is my grease gun not working?

Your grease gun may not be working due to clogged with old or hardened grease, the nozzle might be blocked, or there could be air trapped in the system. Additionally, the grease cartridge might be empty or improperly installed, or the gun’s mechanism could be damaged. Check for these issues, clean or replace parts as needed, and ensure proper assembly to restore functionality.

Why won’t grease come out of my grease gun?

If grease doesn’t come out of your grease gun, it could be due to air trapped in the system, a clogged nozzle, or a damaged seal. Ensure the gun is properly primed by pumping it until grease flows smoothly. Check for blockages in the nozzle and clean it if necessary. Also, inspect the seals and replace them if worn. Using the correct grease cartridge and ensuring it’s fully seated can also resolve the issue.

Are air grease guns any good?

Air grease guns are highly effective for heavy-duty and frequent lubrication tasks, offering consistent pressure and faster operation compared to manual guns. They are ideal for professional settings like automotive repair or industrial maintenance. However, they require an air compressor, limiting portability, and can be noisy. For occasional use or smaller jobs, manual or battery-powered grease guns may be more practical. Overall, air grease guns excel in efficiency and performance for demanding applications.

Conclusion: What Is A Grease Gun Used for?

A grease gun is a handy tool for adding grease to machines and equipment. It helps keep parts moving smoothly and prevents wear and tear. People use it in cars, trucks, farm tools, and factory machines. The gun pushes grease into tight spots that are hard to reach. This keeps machines working well and saves money on repairs. Regular use of a grease gun extends the life of equipment and ensures it runs efficiently. It’s a simple tool, but it plays a big role in maintaining heavy-duty and everyday machines. Proper care with a grease gun keeps everything running without trouble.

Related articles:

- How to Get a Grease Gun off a Zerk?

- 10 Best Marine Grease Guns: Top Picks for Smooth Sailing

- 3 Best Grease Gun Tips for Smooth Lubrication & Maintenance

- Top 10 Best Grease Gun Couplers (Tested & Reviews 2025)

- 7 Best Grease for Trailer Hitch Ball | Top Picks & Reviews

- Best Grease for Garage Door: Top Picks for Smooth Operation

- 10 Best Car Door Hinge Greases for Smooth Operation